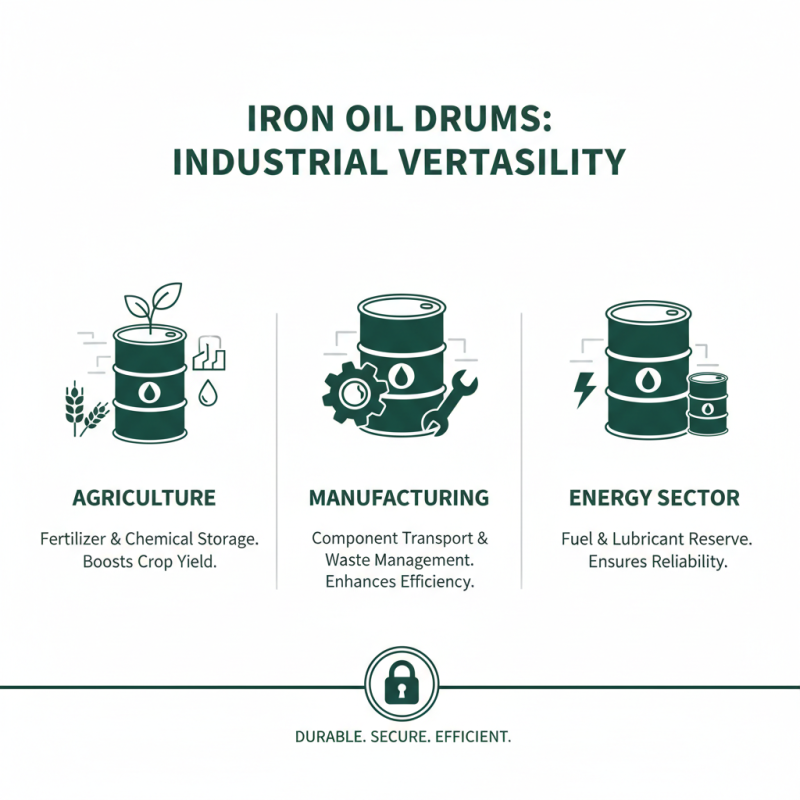

The iron oil drum remains a vital instrument in various industries. Its applications range from safe storage to transportation of oils and chemicals. Innovations surrounding this durable container are shaping the future of industrial storage solutions.

In 2026, trends in iron oil drum technology will spotlight enhanced durability and versatility. Manufacturers are exploring sustainable materials, making drums lighter yet stronger. Voice-activated tracking systems are emerging, ensuring easy monitoring of contents. These advancements connect well with growing eco-consciousness among businesses.

Challenges persist in the industry. Despite innovations, some drums still face issues with leaks or structural failures. Not all designs are user-friendly, leading to safety concerns. As industries continue to evolve, the need for improved standards and quality control becomes clearer. The journey to revolutionizing iron oil drums is far from perfect. However, with ongoing advancements, the future looks promising.

The innovation landscape of iron oil drum production is evolving rapidly. Emerging technologies are reshaping how these drums are designed and manufactured. Innovations such as automated welding and advanced coatings optimize strength and durability. According to recent industry reports, there has been a 30% increase in the use of lightweight materials to enhance efficiency.

These advancements also address environmental concerns. Circular economy practices are gaining traction. Recycling and repurposing materials can reduce waste. Industry insights suggest that over 50% of companies now focus on sustainable production methods. This shift not only lowers carbon footprints but also attracts eco-conscious consumers.

Tip: Consider the lifecycle of your products. Look for ways to incorporate recycled materials. This can improve sustainability and reduce costs in the long run.

It’s crucial to reflect on the challenges these innovations bring. High initial costs can deter smaller manufacturers. Adoption rates may vary widely, leading to market discrepancies. Continuous improvement and adaptation are necessary. The need for skill development in the workforce is evident. Many workers need training in new technologies and processes.

Tip: Provide training programs for your employees. This can enhance productivity and keep your operations competitive. Engage with local technical schools for resource sharing.